How To Repair Broken Terracotta Glue

If y'all are looking for a good glue or adhesive, there are of form so many options out in that location that making the right choice can exist a real challenge. Gluing polypropylene should not exist too difficult, just to become the chore done, you practise want to have the all-time glue for polypropylene, which we are here to help yous find today.

Click here to skip to our recommended choice!

Best Overall

Loctite Super Mucilage Plastics Bonding System

- Like shooting fish in a barrel

- Fast

- Neat and mess-free

J-B Weld 50139 Plastic Bonder Torso

- Easy to employ

- Stress gratis

- High tensile force

3M Scotch-Weld Structural Plastic Adhesive

- Great for non-porous plastics

- Tin can exist used for plastic to metal bonding

- No surface prep required

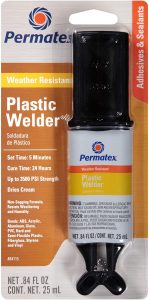

Permatex 84115 5-infinitesimal Plastic Weld Agglutinative

- Works for most all plastics

- High tensile strength

- Ideal for bonding many materials

GLUESMITH- Plastic Repair Glue System

- Great for filling gaps

- Creates equally stiff bond

- Includes a curing accelerator

Professional person Grade Cyanoacrylate

- Very fast curing

- No clamping required

- Works well for many materials

Our Overall #i Rated Selection

Loctite Super Glue Plastics Bonding Arrangement

Of course, the whole point of today's exercise is to detect the best glue for polypropylene, besides equally really good polyethylene mucilage. This means that you demand something that has the power to make very smooth and non-porous plastic stick together, something that is easier said than done.

Well, the overall number ane rated pick for the best polypropylene glue is this Loctite Super Mucilage Plastics Bonding Arrangement.

- Repairs whatever plastic

- No mixing required

- Dries clear

There are many reasons why this is considered to be the best choice for gluing this sort of plastic together. As indicated, this is some very special glue, and it is designed to bond whatever plastic together, whether porous or non.

Moreover, this stuff is just very versatile in general, every bit it has the ability to bail many different materials, and this includes leather, cork, paper, cardboard, wood, chipboard, fabric, metal, ceramic, safe and hard plastics.

Next, hither yous get the primer included, and all you have to do is utilize the primer to the plastic surfaces, then apply the glue, then clamp it together equally you wait for it to dry.

Although it won't fully cure for quite a few hours, it volition set enough to allow y'all to take the clamp off subsequently 5 or ten minutes.

People do similar how this Loctite Super Glue Plastics Bonding System dries clear, thus making it ideal for a diverseness of plastic repairs where you don't want to be able to meet or know that it was ever broken in the first place. Many people also adopt this choice as it comes in easy to dispense tubes, and neither of the components are too thin, thus assuasive for mess-complimentary application.

Check Latest Price

Glue for Polypropylene – Buying Guide

Before you go out and purchase just any sometime glue or adhesive to demark polypropylene or polyethylene, there are some really important things that you lot need to know. Let'southward take a look.

What is Polypropylene & Polyethylene

Did you know that polypropylene is actually a plastic, one of the virtually common plastics effectually? This is a thermoplastic polymer, one which is created via chain growth of the propylene monomer. For those that are interested in knowing, the chemic symbol for this specific type of plastic is (C3H6).

This type of plastic is very widely used in diverse applications, such as packaging, as well equally in the cosmos of plastic parts for many different industries. In fact, even fabrics can technically exist made out of polypropylene.

By contrast, polyethylene is really the number i most common type of plastic used today. It's used in packaging, to make decorations, for action figures, films, tubes, and many other plastic things likewise. If you have something made out of plastic in your dwelling, chances are pretty large that it is made out of polyethylene.

Types of Gum for Polypropylene & Polyethylene

Are you short on fourth dimension or only want a quick respond?

Check out our list below for a summary of our results.

- Loctite Super Glue Plastics Bonding System

- J-B Weld 50139 Plastic Bonder Body

- 3M Scotch-Weld Structural Plastic Agglutinative

- Permatex 84115 5-minute Plastic Weld Agglutinative

- GLUESMITH- Plastic Repair Mucilage Arrangement

- Professional person Grade Cyanoacrylate

When it comes to polypropylene glue, the best type of glue to use is a polypropylene agglutinative. With that being said, at that place are many types of glues and adhesives out there that work well for this type of plastic. In fact, any mucilage that works for plastic, whether an adhesive, hot glue, or annihilation else of the sort, should work fine.

Whatsoever gum that says that it can bond plastic should work fine for polypropylene. Super gum does not always work too well for polypropylene, but even certain types of it may do the job. What is of import to know here is that substances like polypropylene and polyethylene are very smooth and have non-porous surfaces, which ways that many types of glue may not work for it.

Many types of mucilage simply bond with porous surfaces. Therefore, when choosing mucilage for polypropylene and polyethylene, you lot demand to cull one that specifically states that it is designed for plastic, especially for not-porous plastic. There is special polypropylene gum out there designed for this exact purpose, and more often than not, it volition be a 2 part adhesive.

With all of that being said, the general consensus is that ane of the all-time glues to use for bonding polypropylene and polyethylene is hot mucilage, such as from a hot gum gun, and generally speaking, the hotter the better.

How to Mucilage Polypropylene & Polyethylene

Every bit long every bit you accept the right kind of adhesive, such as a two component polypropylene and polyethylene glue, yous should be able to mucilage these substances together just fine.

First off, using some sort of cleaner to clean the surfaces is recommended, just to ensure that there is no droppings nowadays that may get in the way of forming a tight bail. If you are using polypropylene gum, it may come up with a primer. If this is the case, apply the primer to both components being gum together.

These primers are designed to allow the mucilage to form a much tighter bond with the underlying plastic. If you are using a ii party epoxy, make sure that it is mixed very well.

A big flim-flam when it comes to gluing both Polypropylene & Polyethylene is that you should apply a very generous amount of the glue in lodge for it to take total effect. At present, information technology does depend on the glue, simply in almost cases, it is recommended that y'all allow the glue to dry out while being held together manually or past a clamp for at to the lowest degree 5 minutes. IN almost cases, information technology may take 12 to 24 hours for it to fully dry, set, and cure.

Of course, you lot may also cull to use a hot glue gun, in which case, but clean both components first, apply a good amount of the hot glue, squeeze the components together (or clamp them), and then allow the gum to fully cool down and dry out.

Beneath, we have included a video that explains using hot glue for bonding polypropylene plastic.

Find The Right Gum For Any DIY Project With 2 Easy Steps!

Commencement Typing... Or "pull-down" the menus were (This) to (That) are to select the materials yous want to Glue 👇👇

Can't detect the right one?

Leave a comment beneath and We'll find the right Gum for Yous!

Polypropylene Adhesive Rubber Tips

Earlier you get started with polypropylene glue and polyethylene mucilage, there are some very of import safety tips for you lot to keep in mind.

- When using any sort of adhesive, wearing gloves is always recommended. About common types of super glue, hot gum, and other similar types easily bond to peel, and this needs to be avoided, as it can actually exist quite painful.

- When using whatever sort of strong adhesive or epoxy, always work in a well ventilated area. Some of these products can release noxious or poisonous fumes that are all-time not inhaled.

- Although not all people do, wearing some center protection is always recommended when working with any sort of adhesive. This is not the kind of thing that you want to go far your eyes.

The Best Glue for Polypropylene

The elevation best product [hibernate]

Loctite Super Glue Plastics Bonding Organization

If you lot demand the best glue for polypropylene, this particular option is one of the best out there, and yes, information technology is 100% guaranteed to bond all plastics, and this includes polyethylene as well. It works well on all sorts of non-porous plastics, merely tin also exist used with other materials such as leather, cork, paper, paper-thin, wood, chipboard, material, metal, ceramic, and rubber.

Information technology is very easy to utilize. Simply apply the primer or activator first, in order to prepare the plastic surfaces, so apply the mucilage, and clamp information technology for a few minutes to allow information technology to set. The Loctite Super Gum Plastics Bonding System is designed to be mess-free, and it doesn't even require you to mix anything. It has to be one of the fastest and easiest glues to apply out there.

Pros

Easy

Fast

Neat and mess-complimentary

Bonds any type of plastic

Bonds much more just plastic

Cons

Dries out in the tube pretty speedily

buy on Amazon

J-B Weld 50139 Plastic Bonder Body

Here nosotros accept another squeamish pick to go with, and this 1 is a two component agglutinative. The product comes with both components inside of a syringe, and both tin can be pressed out at once. Keep in mind that the 2 components practise first need to be mixed for utilise.

What is prissy is that this adhesive takes most fifteen minutes to set, then once you have mixed it, you don't take to rush too much. You will need to clamp the plastics together for most xv minutes, which is not also bad, but keep in heed that it can accept upward to 30 hours to totally cure and dry.

This stuff has a tensile force of over 3,700 PSI, which is very impressive, and it'due south what makes this gum ideal for bonding all sorts of plastics, also as for filling cracks and gaps. This glue tin exist used for various materials including thermoset & carbon fiber composites, thermoplastics and coated Metals, plastic & PVC, concrete, ceramic and tile, fiberglass, and aluminum likewise.

Pros

Piece of cake to use

Stress complimentary

Loftier tensile force

Bonds all plastics

Suitable for many materials

Cons

Long curing time

Mixing required

buy on Amazon

3M Scotch-Weld Structural Plastic Adhesive

If you need a simple adhesive that works well for most kinds of plastic, this is a practiced choice to go with. At present, keep in mind that this is a simple component adhesive, so at that place is no mixing required. Simply clasp it out of the tube and apply it straight to a surface.

It's designed to be a structural plastic adhesive, one that required no or minimal surface prep. Keep in mind that once it is out of the tube, it has a work life of 3 minutes, and so on one mitt, yous do need to work fast when using it, only on the other manus, you don't have to clench anything for very long. It works great for bonding low surface energy plastics without whatever special preparation. It also has the power to bail plastic to metal.

Pros

Great for non-porous plastics

Can be used for plastic to metal bonding

No surface prep required

Fast drying

Easy to use

Can dry almost likewise fast – need to work quick

Cons

Tin can dry most too fast – need to work quick

buy on Amazon

Permatex 84115 5-minute Plastic Weld Adhesive

Here we have a really stiff structural adhesive, one that more than or less welds plastics together. Information technology has a very high tensile strength of 3,500 PSI, making information technology super tough and ideal for structural repairs that demand to be able to handle lots of weight.

This production does not crave any primers or prep. Remember that this is a two part glue that needs to exist mixed first. Information technology sets in about 5 minutes, so y'all do need to work quick, only it also minimizes the demand for clamping. This product tin be used with various materials including ABS, acrylic, fiberglass, FRP, glass, PVC, SMC, steel, styrene, vinyl, and wood. Remember that it does non dry clear.

Pros

Works for almost all plastics

High tensile strength

Platonic for bonding many materials

Fast setting

Easy to apply

Cons

Takes 24 hours to cure

Does not dry clear

purchase on Amazon

GLUESMITH- Plastic Repair Glue System

This is a really neat option to become with, a full plastic repair kit. Here, you become two bottles of filler, which can be used to fill cracks and gaps. Yous likewise go 2 bottles of plastic adhesive that works well to bond all sorts of plastics, fifty-fifty those with low surface free energy. Finally, you also get a and so called booster, which helps to accelerate drying and curing. It might only be the all-time plastic repair kit out there, simply it does have some skill to use and you may besides require primer for sure plastics.

Pros

Great for filling gaps

Creates as strong bond

Includes a curing accelerator

Works well for all plastics

Cons

Does not come with primer

purchase on Amazon

Professional Course Cyanoacrylate

This is instant glue, and yes, information technology dries and cures in a matter of minutes. If y'all need fast acting gum for small repairs, and y'all don't want to have to wait long for it to cure, this is the option to go with. At present, super gum is non the best option for plastics such as polypropylene, withal, if yous use a primer first, it should non exist an issue. This stuff is thin enough to get information technology where you need information technology to become, but too thick enough so that it doesn't run all over the identify, plus the small dispenser cap makes awarding a cakewalk.

Pros

Very fast curing

No clamping required

Works well for many materials

Cons

May crave a primer for some plastics

purchase on Amazon

Decision

Remember folks, when gluing polypropylene, yous need the right kind of glue. The well-nigh important affair to look for with any production here is that information technology is made to glue non-porous or low surface energy plastics. Equally long every bit you go along this in listen, y'all shouldn't have whatsoever problems finding the all-time glue for polypropylene.

Source: https://gluefaq.com/best-glue-for-polypropylene/

Posted by: newbycantences.blogspot.com

0 Response to "How To Repair Broken Terracotta Glue"

Post a Comment